Commercial Broiler Feed Additive Decision Support

By: Anders L. Madsen (HUGIN) and Jeffrey Hoorfar (DTU)

26 September 2016, latest update 5 July 2018

Introduction

The model deployed on this page is an example illustrating the use of (limited-memory) influence diagrams to support decision making on the use of a feed additive in poultry production (commercial broiler). The decision considered by the farmer is whether or not to use a feed additive in commercial broiler production. This decision is assumed to be made after the house has been emptied and cleaned before filling the house with a new set of birds.

We assume the feed additive is available in crude and purified form. Furthermore, we assume the farmer can decide between providing the feed additive in different time frames, e.g., for the first two weeks or the last three days before slaughter. The decision alternative we consider are none (i.e., no use of a feed additive), crude for the first two weeks, crude for three days pre-slaughter, or purified for three days pre-slaughter. Each option will have a different expected impact on the level of campylobacter at slaughter.

The underlying model is a (limit-memory) influence diagram [Kjaerulff and Madsen, 2013] developed for the Danish market based on the work of [Garcia et al, 2013,Garcia et al, 2016].

The model deployed here implements Reward system 1 [Garcia et al, 2016].

Interactive Front-end

Below are some HUGIN widgets for interacting with the model. This interface has been developed using the HUGIN Web Service API [Madsen et al, 2013].

The model is used under the assumption that the farmer at the time of decision knows the value of a set of risk factors related to farm characteristics, system variables and observations. The five risk factors included in the model are shown on the far left where the user is expected to select the corresponding value for each risk factore. The middle column shows the decision alternatives under the heading Feed additive. Below the decision alternatives the cost, reward and combined cost and reward are shown. On the far right, the expected impact of the selected decision alternative is shown.

Farm Characteristics, System Variables and Observations

Decision

The expected selling price at slaughter is .

The expected cost of the feed additive is .

This means that the expected profit is .

Decision Impact

The expected logs reduction is

The expected campylobacter level at slaughter is

Example Scenarios

[Garcia et al, 2016] define the best or baseline case scenario as follows:

- winter,

- age of broilers at slaughter less than or equal to 35.5 days,

- number of persons equal to one,

- a negative previous flock history, and

- age of poultry house after 1990.

Similarly, [Garcia et al, 2016] define the worst case scenario as follows:

- summer,

- age of broilers at slaughter larger than 35.5 days,

- number of persons higher than one,

- a positive previous flock history, and

- age of poultry house before 1990.

The Decision Model

The figure on below shows the structure of the decision model deployed on this page.

The purpose of the decision model is to support decision making (under uncertainty) at the operational level, e.g., to support decisions made for each chicken flock. The model does not consider decision making at the more strategic level as, for instance, the use of fly screens. The model could take into consideration the presence or absence of fly screens.

The decision model has five main components:

- Risk factors: The model includes five risk factors (orange nodes in the graph).

- Alternatives: The boxed shaped node in the graph represents the decision node, which has one state for each intervention option including no intervention.

- Effectiveness: The blue node implements the efficiency of the intervention in log CFU/g reduction. If there is no intervention, then there is no impact and no reduction.

- Cost system: The cost of the intervention. No action has no cost. The costs of the interventions are shown in a table below.

- Rewards system: The reward given to the farmer depends on the (measured) level of Campylobactor concentration at slaughter time. The reward system is discussed in the paragraph below.

In addition to the graphical structure, the model is quantified using probabibilities and utilities as discussed in the following two sections.

The decision problem represented by the model is solved by determining the policy for the decision node. The policy will identify the best option to take for each possible scenario (as defined by the risk factors represented in the model). The policy is a function of the node having arcs going into the decision node to the states of the decision nodes (i.e., the decision alternatives).

Cost and Reward System

In their work, [Garcia et al, 2013] and [Garcia et al, 2016] designed two different reward

systems based on the

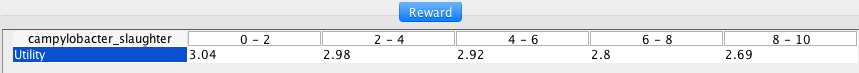

Reward system 1 as show in the table below is designed based on a system implemented in Denmark where the producers get a reward when the flock is identified as negative at the time of slaughter, [Garcia et al, 2016].

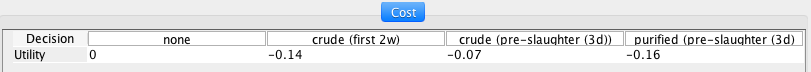

The cost of each possible intervention included in the model is shown in the table below. There is no cost associated with the no action, and the costs / chicken of the three interventions (administrer the crude feed additive for the first two weeks, the crude feed additive for the last three days before slaughter, or the purified feed additive for the last three days before slaughter) are DKK 0.14, 0.07 and 0.16, respectively.

The model should support the farmer to make the best decision where considering the use of the feed additive to reduce the concentration of Campylobacter at slaughter time taking the risk factors such as, for instance, bio-sercurity, sesonality and other factors of the farms into consideration.

Probabilities

Each oval node in the decision model represents a random variable. Each random variable has a probability distribution over its possible states given each configuration of its parents in the graph, if any. This means, for instance, that each risk factor has a marginal distribution while the node representing the effectiveness of the intervention is conditional on the decision and the delivery system (the node delivery system is included in the structure of the model only for illustrative purposes. It has no impact on the effectiveness. The delivery system is part of the decision options).

The model has two main sets of probability distributions. The first set relates to the risk factors and the second relates to the effectiveness of the interventions. The probabilities related to the risk factors have been computed by [Garcia et al, 2016] using the odds-ratios provided by [Chowdhury et al, 2012], while the effectiveness of the interventions are based on simple estimates.

References

[Anon, 2010] Anon, 2010. The Joint Government And Industry Target To Reduce Campylobacter In Uk Produced Chickens By 2015 December 2010. Available online here.

[Crane et al, 2011] Crane, R., Davenport R., and Vaughan, R., 2011. Farm Business Survey 2009/2010. Poultry production in England. Available online here

[EFSA, 2010] Analysis of the baseline survey on the prevalence of Campylobacter in broiler batches and of Campylobacter and Salmonella on broiler carcasses in the EU, 2008, part A: Campylobacter and Salmonella prevalence estimates. EFSA Journal 2010; 8(03):1503. Available online here

[Lawes et al, 2012] Investigation of prevalence and risk factors for Campylobacter in broiler flocks at slaughter: results from a UK survey. Centre for Epidemiology and Risk Analysis, Animal Health and Veterinary Laboratories Agency, Surrey, UK. Epidemiol Infect. 2012 May 25:1-13. Lawes JR, Vidal A, Clifton-Hadley FA, Sayers R, Rodgers J, Snow L, Evans SJ, Powell LF. [Epub ahead of print].

[Madsen et al, 2013] Madsen, A. L., Karlsen, M., Barker, G. C., Garcia, A. B., Hoorfar, J., Jensen, F (2013). A Software Package for Web Deployment of Probabilistic Graphical Models. In Proceedings of the Twelfth Scandinavian Conference on Artificial Intelligence (SCAI), pages 175-184.

[Garcia et al, 2013] Garcia, A. B., Madsen, A. L. and Vigre, H. (2013). Integration of Epidemiological Evidence in a Decision Support Model for the Control of Campylobacter in Poultry Production, Agriculture, 3(3), pages 516-535.

[Garcia et al, 2016] Garcia, A.B., Madsen, A.L., Vigre, H. (2016). A decision support system for the control of Campylobacter in chickens at farm level using data from Denmark, Journal of Agricultural Science, 154, pages 720-731.

[Chowdhury et al, 2012] Chowhury, S., Sandberg, M., Themudo, G.E., Ersbøll, A.K. (2012). Risk factors for Campylobacter infection in Danish broiler chickens, Poultry Science, Volume 91, Issue 10, Pages 2701-2709

Useful references for those interested in BBN include:

[Kjærulff and Madsen, 2013] Kjærulff, U. B. and Madsen, A. L. (2013) Bayesian Networks and Influence Diagrams: A Guide to Construction and Analysis. Springer, Second Edition.

Contact information

For further details on the paper: Jeffrey Hoorfar

For further details on the use of Bayesian networks and web deployment of models contact: Anders L Madsen (alm(at)hugin(dot)com)

Disclaimer

HUGIN EXPERT A/S takes no responsibility whatsoever for examples and information in examples published on this web site. ALL EXAMPLES ARE FOR DEMONSTRATION PURPOSES ONLY.